Search

0512-6255 1277

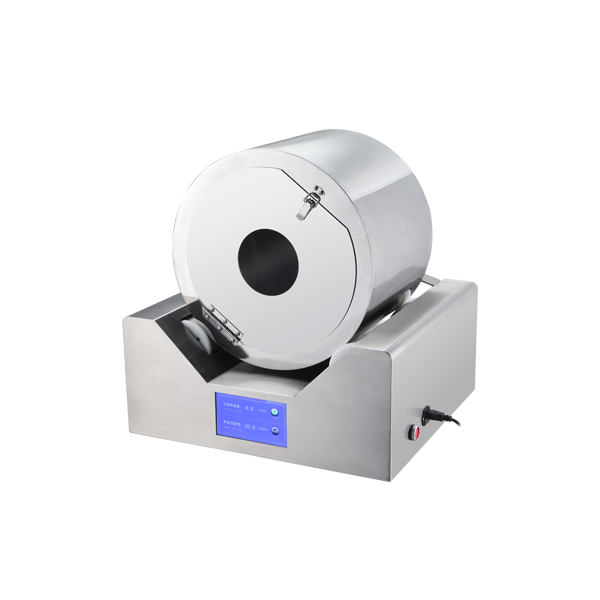

The SX-Z Hamick drum is used to measure the amount of particulate matter emitted by clean fabrics during simulated motion. This motion involves the fabric in a dry state being flipped inside a rotating drum. Within a specified time, a certain amount of samples is taken to measure the quantity or concentration of particulate matter emitted by the fabric. The measured value is then compared with the standard grade to determine the fabric's cleanliness level.

Advantage

• Provide a complete verification manual to facilitate

compliance with pharmaceutical/electronic specifications.

• Built-in thermal printer can print or query in real time.

• Reduce operator error, perform long-term data

archiving, and support long-term data storage.

• Clean service testing, environmental monitoring.

• Audit tracking, personnel operation record storage.

• Sampling areas and grade standards can be preset.

• GMP, ISO 14644.1 cleanliness standard judgment.

• It was verified according to JJF 1190-2008 and GB/T

6167-2007.

• 7-inch touch screen, simplified operation.

• GB/T 24249-2009 Anti-static clean fabric.

• IEST-RP-CC003.5 Clothing systems for clean rooms

and other controlled environments.

Function

• Sampling flow rate: 28.3L/min ±5% (1 CFM)

• Particle size distribution error: ±30%FS

• Error of indicated concentration: ±30%FS

• Self-cleaning time: less than 10min

• Relative error of repeatability: less than or equal to

10%FS

• Complies with GMP static, GMP dynamic and

ISO14644-1 standards

• Sampling concentration: 35,000 particles/l

• 5000 stored data

• Roller speed: 1~20rpm adjustable

Apply

|

Model |

SX-ZT |

|

Roller speed |

1~20rpm adjustable |

|

Counter model |

SX-L310T |

| Sampling flow | 28.3L/ min ±5% (1.0 CFM) |

| Particle size channel | 0.3μm,0.5μm,1.0μm,3.0μm,5.0μm,10.0μm |

|

Laser light source |

Laser diode |

|

Imported fan |

Continuous operation is stable, energy saving and environmental protection |

|

Verification criteria |

JJF1190-2008,GB/T6167-2007 |

|

Relative error of repeatability |

≤10%FS |

|

Particle size distribution error |

≤±30% |

|

Particle concentration indication error |

≤±30%FS |

|

Maximum sampling concentration |

35,000 particles /L |

|

Self-cleaning time |

≤10min (counting is zero for 3 consecutive times within 10 minutes, 95% confidence) |

|

Sampling time |

User set (1~14400 seconds) |

|

Sampling delay |

User set (1~255 seconds) |

|

Number of sampling points |

2~50 |

|

Number of samples (location) |

2~50 |

|

Operate time |

The continuous test time is 6 hours with full charge |

| Video display | Color 7-inch touch screen |

|

Print mode |

Built-in thermal printer |

|

Charge power supply |

Communication (220V/50Hz)) |

|

Built-in lithium battery |

DC14.8V 36Ah |

|

Charging adapter |

Input 100V-240V 2.5A, output 16.8V 5A |

| Battery charging time | 6 to 8 hours |

|

Air cleanliness grade determination standard |

ISO 14644.1, GMP dynamic, GMP static |

| Standards for judging clean clothes | GB/T 2429 Anti-static clean fabric |

|

Data communication interface |

USB |

|

Environmental requirements |

Usage environment: temperature 0~40℃ relative humidity 10~70%RH |

|

Storage environment: temperature-30~45℃ relative humidity 0~90%RH |

|

| Roller external dimensions | Length 570 x width 520 x height 600 (mm) |

|

Counter dimensions |

Length 315 x width 320 x height 310 (mm) |

|

Material quality |

SUS304 stainless steel |

|

Power |

≤0.5KW |

|

Total weight

|

≤50kg

|

Submit the form below to contact us now.