Dalian Yalifeng Biopharmaceutical Co., Ltd., with a registered capital of 52 million RMB, is a wholly-owned subsidiary of Shanghai Fosun Pharmaceutical Industry Development Co., Ltd. and serves as the only biological vaccine industry platform under Shanghai Fosun Pharmaceutical Group.

The company has currently completed an investment of approximately 300 million RMB, with a construction area of 20000 square meters, including influenza vaccine raw material production workshop, rabies vaccine raw material production workshop, sub packaging workshop, quality control center, animal laboratory, raw material warehouse, finished product warehouse, administrative office, and life support areas. At the same time, the company has a research and development laboratory in the Shuang D Port Biotechnology Industrial Park in the development zone, which serves as an incubation base for subsequent research and development products.

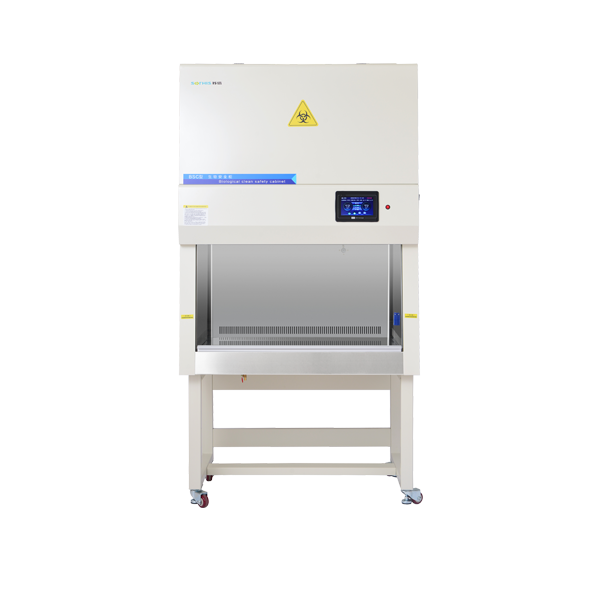

Recently, Dalian Yalifeng Biopharmaceutical Co., Ltd. purchased an SX-1300 IIB2 biosafety cabinet from Suzhou Suxin Environmental Technology Co., Ltd. During the installation process, Yalifeng Company found that the air volume in the installation room was insufficient and needed to borrow air from outside the room. Su Xin helped solve the problem by adding an intake duct and a medium to low efficiency filter.

The SuXin SX-BHC series biosafety cabinet is a biosafety isolation equipment used in biosafety laboratories or other laboratories to protect personnel, test samples, and the environment. It can meet the requirements of hazard levels 1, 2, 3, and other pathogen operations.

The SX-BHC series biosafety cabinet belongs to Class II biosafety cabinet. The negative pressure airflow sucked in from the front opening area is used to protect the safety of personnel, and the vertical airflow through the high-efficiency filter (HEPA) is used to protect the safety of the test samples. The exhaust gas is filtered through the high-efficiency filter to protect the environment from pollution.

Our company is a participating unit in the national standards "Performance Test Method for Dust Particle Counter" and "Biosafety Cabinet" industry standards. We are a professional company that integrates the design, research, development, manufacturing, installation, and operation of purification equipment, purification detection instruments, and purification engineering.

Performance characteristics:

1. A 10 ° tilt angle design that conforms to ergonomic principles provides a better operating experience;

2. The shell is made of high-quality cold-rolled steel plate and electrostatically sprayed with plastic; The three sides of the safety cabinet operation area are made of stainless steel (SUS304) integrated structure, with 8mm rounded corners inside for easy cleaning;

3. Vertical laminar negative pressure machine, with 30%/100% filtered discharge of return air;

4. Unique internal safety negative pressure design, air curtain isolation, ensuring no leakage under normal use and ensuring the safety of operators;

5. A bracket type safety cabinet, where the bracket can be separated from the upper box for easy handling and positioning;

6. The exhaust system is equipped with a dedicated high-efficiency filter to ensure that the discharged air meets national standard requirements;

7. Integrated sliding safety sliding door, can be positioned arbitrarily, easy to operate, and can be completely closed for sterilization;

8. Equipped with filter failure alarm, supply fan overload alarm, and working window opening limit alarm system;

9. Equipped with dedicated waterproof sockets and drainage interfaces to provide great convenience for operators.

| BHC series biosafety cabinet | SX-BHC-1000A2 | SX-BHC-1300A2 |

| Cleanliness level | ISO5(Class100)/ISO4(Class10) | |

| Filter level/filtration efficiency | HEPA/ULPA ≥99.995~99.999% @0.3μm | |

| Downdraft | 0.25~0.45m/s | |

| Average flow velocity (m/s) | ||

| Inflow airflow | ≥0.5m/s | |

| Average flow velocity (m/s) | ||

| Noise | ≤65dB(A) | |

| Vibration peak value | ≤5μm | |

| Power supply | AC single-phase 220V/50Hz | |

| Airflow balance biological control | Personnel protection 1-8CFU/ml (repeated 3 times, 5 minutes/time) | |

| a. Total colony count of impact sampler: ≤ 10CFU/time | ||

| b. Total bacterial count of slit sampler: ≤ 5CFU/time | ||

| Product protection 1-8CFU/ml (repeated 3 times, 5 minutes/time) Total bacterial count: ≤ 5CFU/time | ||

| Cross contamination protection 1-8CFU/ml (repeated 3 times, 5 minutes/time) Total bacterial count: ≤ 2CFU/time | ||

| Higher power (KV)· | 0.8 | |

| Airtightness (KV)· | Leakage rate under 500Pa pressure ≤ 10% (within 30 minutes) | |

| Weight (Kg) (KV)· | 300 | |

| Work area dimensions W * D * H (mm) | 1000*620*620 | 1300*620*620 |

| Device dimensions W * D * H (mm) | 1200*780*2160 | 1500*780*2160 |

| Specification of air supply filter | 1040*445*50① | 1340*445*50① |

| And quantity | ||

| Specification of exhaust filter | 665*410*50① | 965*410*50① |

| And quantity | ||

| Specification and quantity of fluorescent lamps | 30W③ | 40W③ |

| Specification and quantity of ultraviolet lamps | 30W① | 40W① |

| Illuminance | 650Lx | |

| Diameter of supply and exhaust ducts | Φ250mm | |

| Wind direction | Top out | |

| Notes | Split up and down | |

| The above dimensions are for reference only and are subject to actual needs and design dimensions. Customization of non-standard products is accepted, and delivery time and price need to be negotiated | ||