In the modern pharmaceutical industry, the cleanliness of the production environment directly affects the quality and safety of drugs. Particulate and microbial contamination in the air may have irreversible effects on drugs and even endanger patient health. The traditional environmental monitoring methods can no longer meet the increasingly strict quality supervision requirements, and real-time online monitoring systems are gradually becoming an important tool to ensure the production environment of drugs.

Why do we need a real-time online monitoring system?

Pharmaceutical production has extremely strict requirements for environmental cleanliness. Dust particles not only have the potential to directly contaminate drugs, but also serve as carriers for microbial attachment, and their quantity often directly reflects the degree of microbial contamination in the environment. The 2010 version of GMP regulations clearly requires dynamic monitoring of cleanroom Class A and Class B areas, which poses higher technical requirements for pharmaceutical companies.

The traditional manual monitoring method has obvious limitations: it cannot provide continuous monitoring data, it is difficult to timely detect deviations from the specified working conditions of the system, and it is also unable to accurately evaluate product quality. Therefore, a new system with real-time online monitoring function has become an inevitable choice for quality assurance in the pharmaceutical industry.

The core components of an online environmental monitoring system

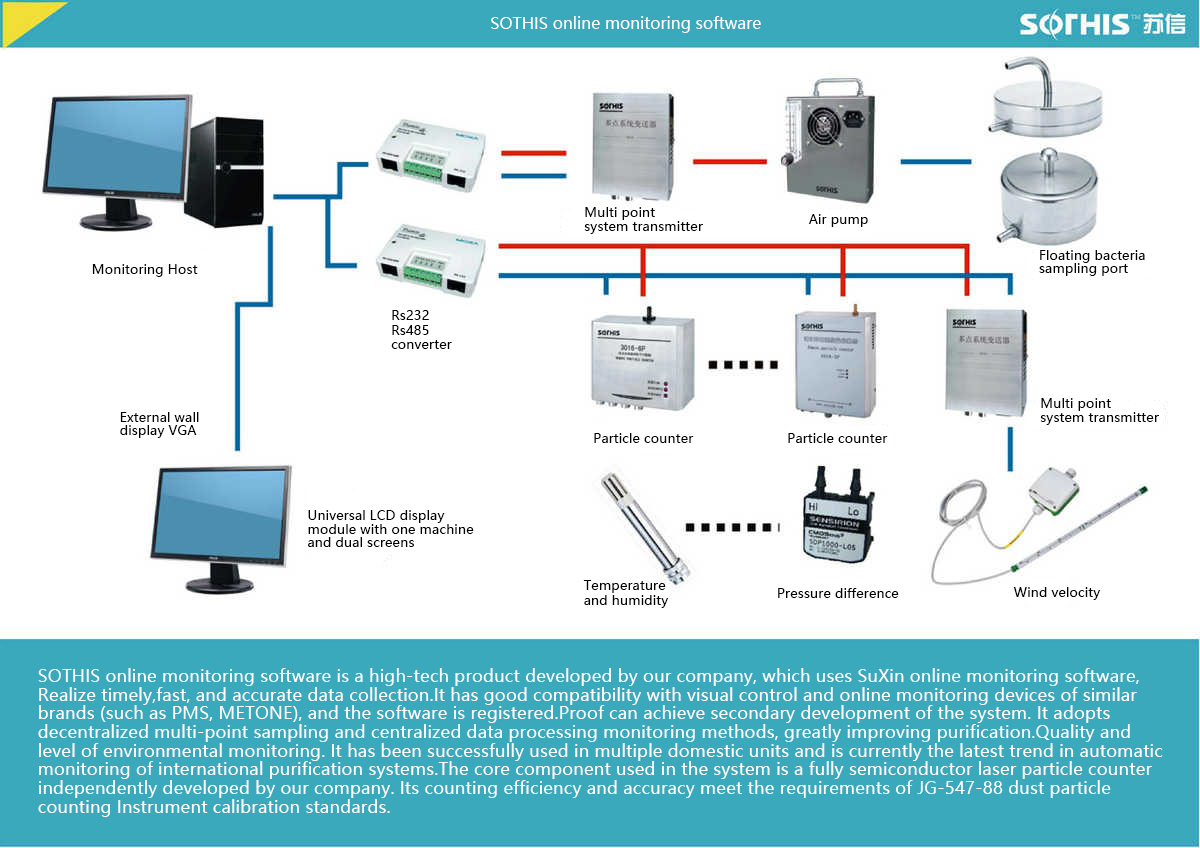

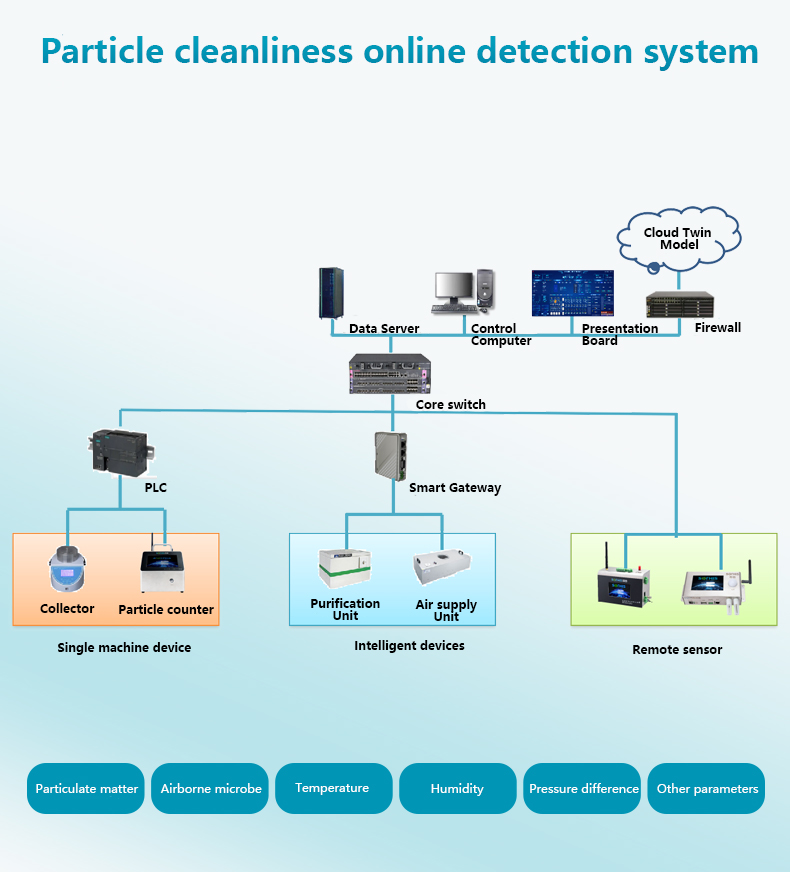

A complete online environmental monitoring system consists of multiple precision modules, which together build a comprehensive environmental monitoring network:

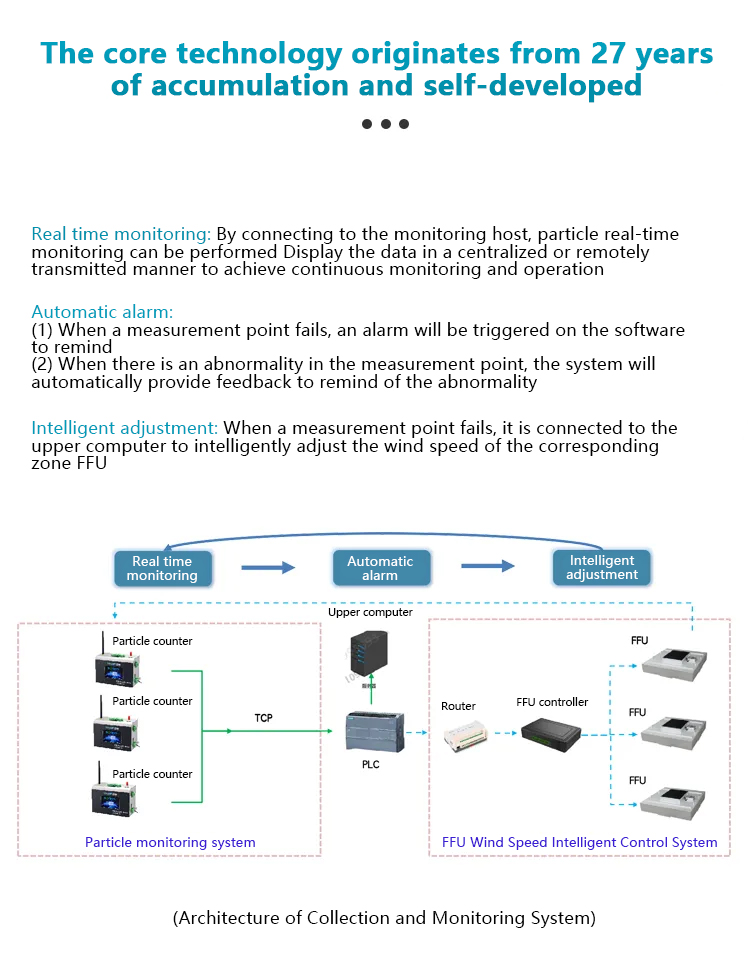

Data Collection Layer

-Online particle counters (such as models 3016-3P and 3106-6P): Real time monitoring of the number of particles of different sizes in the air

-JCQ-2 Floating Bacteria Sampler: Collecting and Monitoring Microbial Pollution in the Environment

-Temperature and humidity sensor: continuously monitoring environmental temperature and humidity parameters

-Differential pressure sensor: Ensure that the pressure difference in the clean area meets the requirements

-Wind speed sensor: maintain stable airflow organization in the clean area

Data Processing Layer

-Signal converter (RS232 to 485): realizing the conversion and transmission of data signals

-Monitoring computer: Central processing unit responsible for data storage and analysis

-Touch screen: Provides a human-computer interaction interface for easy operation and inquiry

Output control layer

-Central centralized pump and independent pump: providing sampling power source

-Alarm: Promptly sound an alarm when parameters exceed the standard

These modules work together to build a 24/7, uninterrupted environmental monitoring system that can provide real-time feedback on production environment conditions, ensuring that any deviations can be immediately detected and addressed.

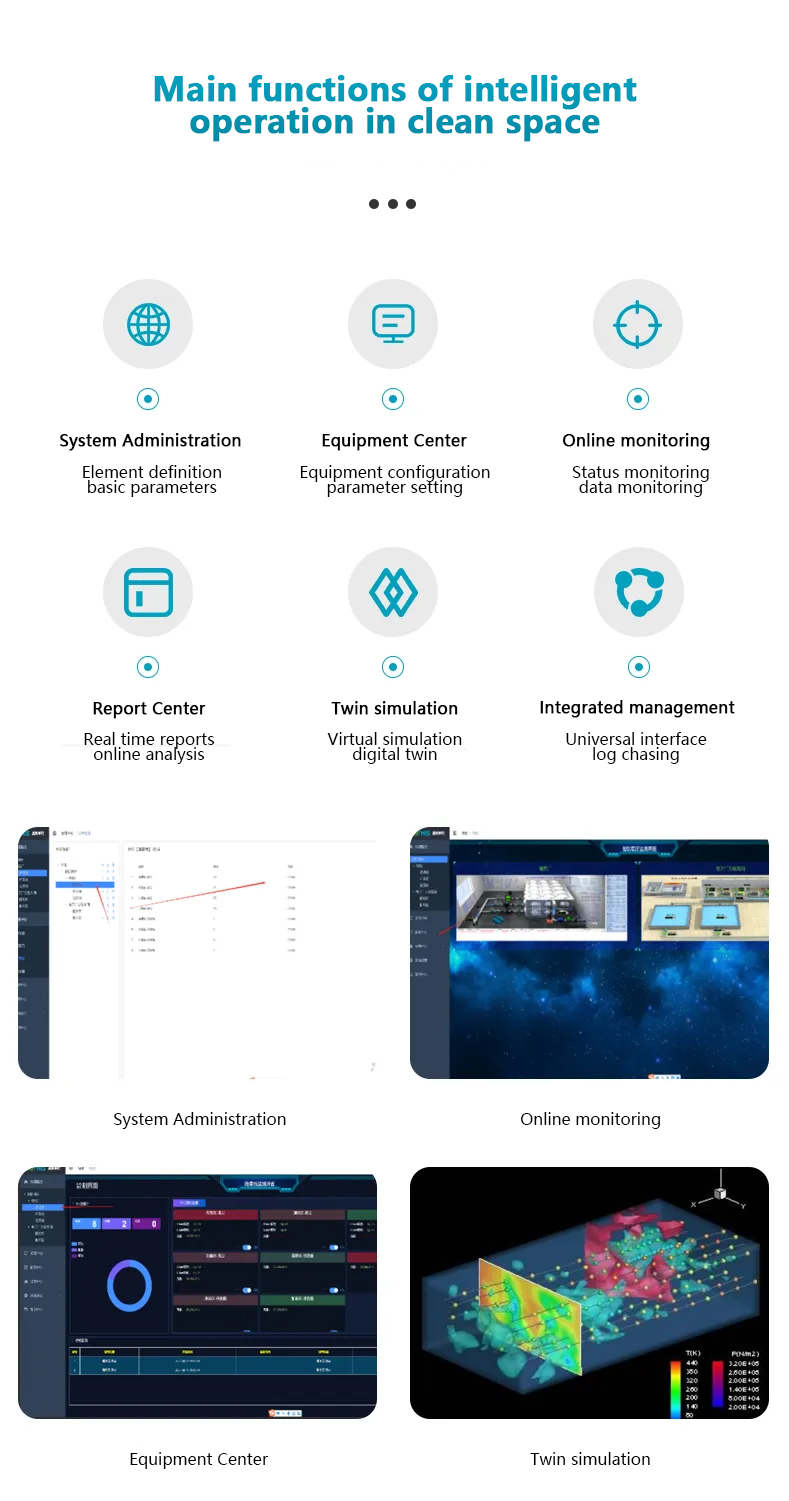

System advantages and application value

The application of online environmental monitoring systems has brought multiple values to pharmaceutical companies:

1. Implement 24-hour continuous monitoring to eliminate blind spots in monitoring

2. Instantly detect abnormal situations and take corrective measures quickly

3. Comply with GMP regulations and meet regulatory expectations

4. Reduce product quality risks and ensure patient medication safety

5. Improve quality management efficiency and reduce labor costs

With the continuous improvement of quality standards in the pharmaceutical industry, online environmental monitoring systems have evolved from "optional accessories" to "essential facilities". It not only represents the technical level of quality control in pharmaceutical companies, but also the best practice of the concept of "quality comes from design" in enterprises.

In the future, with the further development of the Internet of Things and big data technology, environmental monitoring systems will become more intelligent and automated, providing the pharmaceutical industry with more comprehensive and accurate environmental protection solutions, and becoming a solid barrier to safeguard drug quality and safety.