In the pharmaceutical industry, the cleanliness of the production environment directly affects the quality of drugs and patient safety. With the increasing requirements of GMP for dynamic monitoring, traditional manual monitoring methods are no longer able to meet the demands. The online environmental monitoring system has emerged as a key technical means to ensure the production environment of drugs. This article will delve into the necessity, composition modules, and implementation process of an online environmental monitoring system.

The necessity of real-time monitoring

The production environment of the pharmaceutical industry has a decisive impact on the quality of drugs. Suspended particles in the air and microorganisms attached to them are the main sources of pollution, which not only directly contaminate drugs but may also alter their performance. Research has shown that the number of dust particles is positively correlated with microbial content, making real-time monitoring of dust particles crucial for controlling pollution. The 2010 version of GMP explicitly requires dynamic monitoring of cleanroom Class A and Class B areas, which requires pharmaceutical companies to adopt more advanced monitoring technologies.The traditional manual monitoring method has obvious shortcomings, as it cannot provide continuous monitoring data and is difficult to accurately determine when the environment deviates from the specified working conditions. This lag greatly increases product quality risks and cannot meet the requirements of modern pharmaceutical industry for process control. The online environmental monitoring system can collect real-time data, detect abnormal situations in a timely manner, and provide reliable environmental protection for drug production, making it the preferred solution for product quality assurance in the pharmaceutical industry.

Composition of System Core Modules

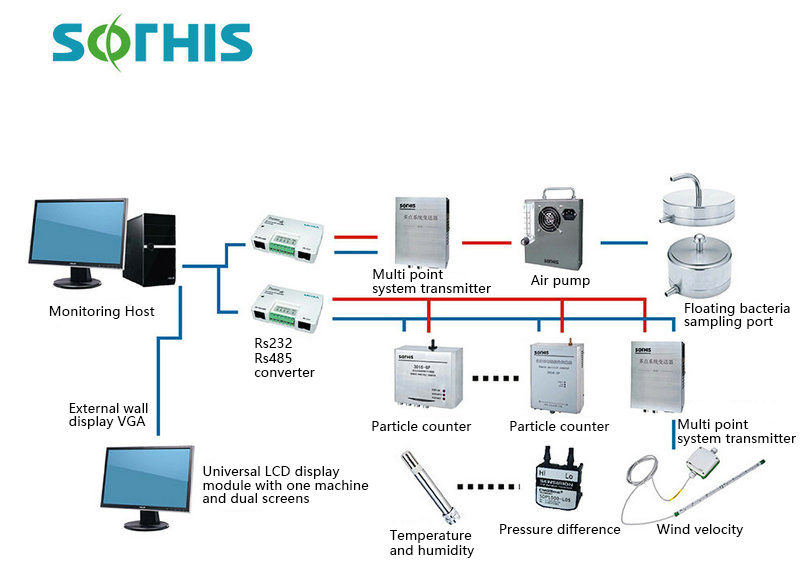

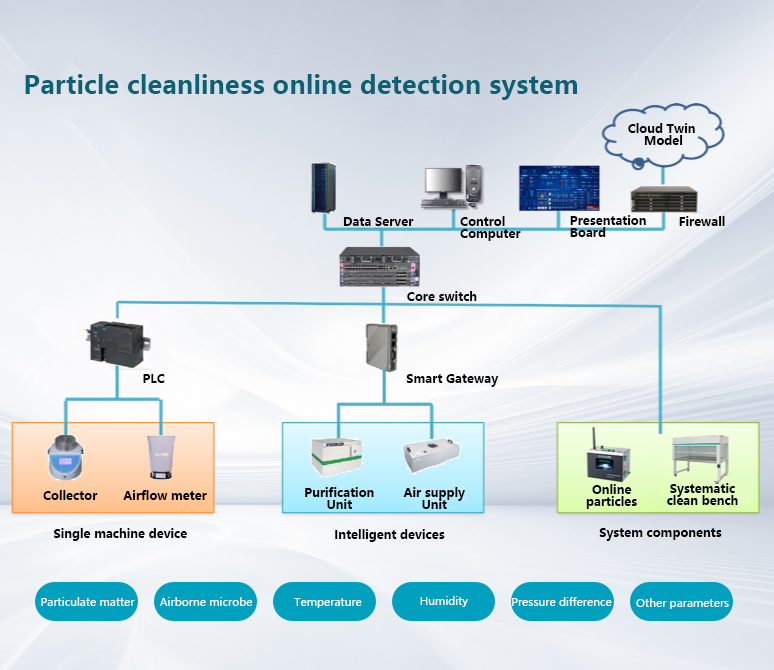

The online environment monitoring system consists of multiple professional modules, each of which is responsible for specific monitoring functions. The monitoring computer, as the core of the system, is responsible for data collection, processing, and display; Signal converter (RS232 to 485) ensures the stability of data transmission; The online particle counters (3016-3P and 3106-6P) are key devices for monitoring dust particles, capable of real-time detection of the number of particles of different sizes. The collaborative work of these modules constitutes a complete monitoring network.

System overall framework design

The overall framework of the online environment monitoring system adopts a distributed architecture, and each monitoring point is connected to the central control room through a fieldbus. This design ensures real-time data collection and facilitates system expansion and maintenance. The system framework is usually divided into a perception layer, a transport layer, and an application layer: the perception layer is composed of various sensors and is responsible for collecting raw data; The transport layer achieves data transmission through industrial buses or wireless networks; The application layer completes data processing, storage, analysis, and display.

In the framework design, the layout of the sampling pipeline is particularly important, and it needs to be planned reasonably according to the actual situation of the clean room to ensure the representativeness and sampling efficiency of the sampling points. At the same time, the system should have good compatibility and scalability, and be able to flexibly adjust according to changes in monitoring requirements. The wiring of power and signal lines also needs to follow relevant specifications to avoid interference and safety hazards. A scientifically reasonable system framework design is the foundation for ensuring the stable and reliable operation of online environmental monitoring systems.

Preparation work before construction

The construction of an online environmental monitoring system is a systematic project, and preliminary preparation work is crucial. Firstly, it is necessary to go deep into the construction site, have a detailed understanding of the layout, structure, and existing facilities of the clean room, and fully communicate monitoring requirements with the client. On this basis, on-site point confirmation is carried out, considering the representativeness and operability of the sampling points, to ensure that the monitoring data can truly reflect the environmental conditions. The location plan needs to be reviewed and approved by the client to form the final construction basis.

After confirming the location, a detailed sampling pipeline diagram needs to be drawn, including parameters such as pipe diameter, direction, and length. At the same time, materials such as sampling tubes, cables, connectors, etc. will be procured according to construction requirements. Before formal construction, it is necessary to coordinate with all parties, determine the construction time and precautions, and minimize the impact on normal production. Adequate preliminary preparation can effectively avoid problems during the construction process and ensure the smooth implementation of the project.

System installation and debugging process

System installation is a critical step in the construction process and requires strict adherence to regulations. Firstly, carry out drilling operations to create conditions for the installation of sampling tubes and cables, while paying attention to protecting the structural integrity of the clean room. Subsequently, confirm the location of the interlayer points to ensure a reasonable layout of the sampling pipeline. Next, lay the main power line and signal line conduit, and then lay and wire the pipelines and cables of a single instrument. After all wiring is completed, wiring confirmation must be carried out to ensure correct and error free connections.

System acceptance and operation management

System acceptance is the final stage of project implementation and an important link in ensuring system quality. Acceptance usually includes three parts: document review, on-site testing, and performance verification. The document review mainly checks whether the construction records, commissioning reports, operation manuals and other technical materials are complete and standardized; On site testing to verify the installation location, sampling efficiency, and data accuracy of each monitoring point; Performance validation is conducted through simulation testing to confirm the stability and reliability of the system under various operating conditions. Only after comprehensive acceptance can the system be officially put into use.