1、 Background introduction

SuXin Environmental Technology Co., Ltd.:

Suxin was founded in 1997 and is a provider of comprehensive solutions for intelligent operation in controlled environments. Its hardware includes particle sensors, various environmental detection instruments, local purification equipment, and consumables.

Suxin is rooted in the application of clean technology through one-stop research and development, design, supply chain, sales, and service. Its business covers a wide range of industries such as biomedicine, medical devices, semiconductors, new energy, electronics and precision machinery, aerospace, etc.

Suxin, with nearly 30 years of industry experience and first-class research and development capabilities in China, has won multiple patents for invention, utility model, and computer software copyright registration, and has become a participating and standard setting unit in several sub fields of the clean industry.

SGS:

SGS is an internationally recognized testing, inspection, and certification body, known as the benchmark for sustainable development, quality, and integrity. SGS has over 99600 professional employees distributed across a service network of over 2600 branches and laboratories. Up to now, SGS's business includes seven strategic maps: interconnection and products, industry and environment, nutrition and health, natural resources, management and assurance, sustainable development, digital technology and innovation.

SGS Tongbiao Standard Technical Services Co., Ltd. (SGS Tongbiao) was established in 1991 as a joint venture between SGS Group and China Standard Technology Group, a subsidiary of the State Administration for Market Regulation. SGS Tongbiao is based on the business segments of the group and provides comprehensive quality solutions such as testing, inspection, certification, training, and calibration for sub industries such as agriculture and food, consumer goods, minerals, petrochemicals, industry, energy, automobiles, environment, and biomedicine through a domestic service network consisting of over 16000 former professional employees, more than 100 branch offices, and over 200 laboratories.

2、 Collaboration service content

High purity air is essential for control processes in clean rooms, factory manufacturing, process workshops, and other scenarios. Whether it is the manufacturing of microelectronic processors or various precision products, the pollution of small particles will have a specific impact on the performance of the products. Therefore, the space environment must control particles within a limited range. The filtration testing service ensures that the filters and systems used for filtering particulate pollutants in the system can reliably and effectively remove particles and meet relevant standard requirements.

Due to the short testing cycle and the ability to provide corresponding urgent testing services according to customer needs, comprehensive filtering performance testing services can ensure that your product meets both regulatory requirements and consumer needs.

The semiconductor and compressed air machine HCAC filter performance testing and certification service jointly launched by Su Xin and SGS includes but is not limited to the following aspects:

Resistance performance curve: Evaluate the pressure loss of the filter at different wind speeds or flow rates, providing customers with intuitive data on the efficiency of the filter operation.

0.008 μ m to 50 μ m particle removal efficiency: Test the filter's ability to remove various particles, including oily aerosols, salt aerosols, standard latex microsphere particles, and dust, to ensure the effectiveness of the filter in different particle size ranges.

EPA, HEPA, and ULPA filtration efficiency (MPPS - Most Penetrating Particle Size Determination): Conduct filtration efficiency tests on EPA (High Efficiency Air Filters), HEPA (High Efficiency Particulate Air Filters), and ULPA (Ultra High Efficiency Air Filters), especially at the Most Penetrating Particle Size (MPPS), to evaluate their highest level of filtration performance.

Dust holding capacity and life cycle comprehensive energy efficiency: measures the total amount of particulate matter that the filter can capture before reaching a specific pressure drop increase, while evaluating its energy efficiency performance throughout its entire life cycle, to help customers optimize maintenance and replacement cycles.

Rating and Standard Compliance: Evaluate MERV (Minimum Efficiency Reporting Value) rating according to ASHRAE 52.2 standard, ePx value according to ISO 16890 standard, GWMF (Particle Mass Median Diameter) rating according to EN 779, or C1 to YG rating according to GB/T 14295, to ensure that the filter complies with international and industry standards.

LRV efficiency test (Log Reduction Value): evaluates the removal efficiency of filters on microorganisms (such as bacteria and viruses), quantified by calculating the logarithmic reduction in the number of microorganisms before and after treatment.

HVAC Filter CEC Certification: Provides CEC (California Energy Commission) certification services for filters in HVAC systems to ensure compliance with California and international energy efficiency standards.

3、 Scope of tested products

The testing scope of this collaborative service is extensive, covering the following main types of filters:

HVAC filters: Air filters used in HVAC systems, including primary, medium, high, and ultra-high efficiency filters, aimed at improving indoor air quality.

Compressed air filter: a filter designed specifically for compressed air systems, used to remove impurities such as oil, water, dust, etc. from compressed air, protecting subsequent equipment and processes from pollution.

Semiconductor air filter: a filter designed for the special needs of the semiconductor industry, with extremely high filtration accuracy and reliability, ensuring that the cleanliness of the production environment meets the requirements of semiconductor manufacturing processes.

High efficiency and ultra high efficiency filters: including HEPA and ULPA filters, widely used in occasions that require extremely high air cleanliness, such as hospital operating rooms, laboratories, electronic factories, etc.

4、 Common testing standards

USA testing standards

IEST RP CC001, CC007, CC021

ASHRAE 52.2

AHAM AC-1

ASTM series

NIOSH TEB-APR-STP-0059

EU testing standards

EN 1822-1,-2,-3,-5IEC 60335-2-69 (Annex AA)

EN 779

EN13274-7

DIN 71460 PART1

International testing standards

ISO 11155-1ISO 5011

ISO 16890

CN standard testing standards

QC/T 795.1,795.2GB/T 20291.1-2014

GB/T 13554-2008

GB/T 14295-2019

GB 2626

5、 Service advantages

Technical strength:

Suxin and SGS have strong technical strength and rich experience in their respective fields, and can provide professional testing and certification services to customers.

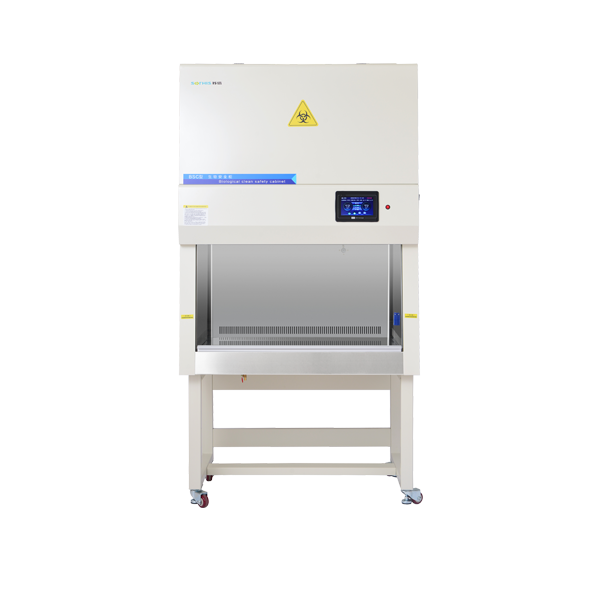

Advanced equipment:

The laboratory is equipped with multiple professional testing instruments to ensure the accuracy and reliability of the test results.

Service Network:

SGS has a global service network that can provide cross-border service support to customers.

One stop solution:

Provide a one-stop solution from testing to certification, helping customers simplify processes and improve efficiency.

6、 SGS IBR Suzhou Laboratory Exhibition

|

F1977 Test Bench Test product: Car passenger cabin air filter Filter element Vacuum cleaner (wired, wireless, robotic vacuum cleaner) |

|

|

5011 Test Bench

Measurement content:

Flow resistance (pressure difference) flow curve

Efficiency test of weighing method

Dust holding capacity (A2 ash, A4 ash) |

|

HVAC filter testing bench Measurement product: Heating, Ventilation, and Air Conditioning (HVAC) Measurement content: Initial filtration efficiency Pollution carrying capacity (DHC) Pressure difference (flow curve) MERV |

|

|

SX-16890 General Ventilation Test Stand (supplied by Su Xin)

Summary:

According to the ISO16890-2016 standard, the test bench is mainly used for testing general ventilation air filters, and the filters are classified (particulate matter ePM) based on the performance results determined by the test procedures.

Advantages:

1. The key instruments are all imported brands, and the data is accurate during testing.

2. The installation fixture adopts pneumatic sealing, which is convenient and fast.

3. The testing pipeline adopts a rotating structure, making it more convenient to install filters.

4. Pipeline design uses fluid analysis for airflow simulation, and the design structure can better meet testing standards. |

7、 Summary

The semiconductor and compressed air HVAC filter performance testing and certification service jointly launched by Su Xin and SGS is a deep cooperation between the two companies based on their respective advantages in their respective fields. This service will provide customers with professional, efficient, and reliable testing and certification services, helping them achieve higher production efficiency and product quality in areas such as semiconductors and compressed air machines.