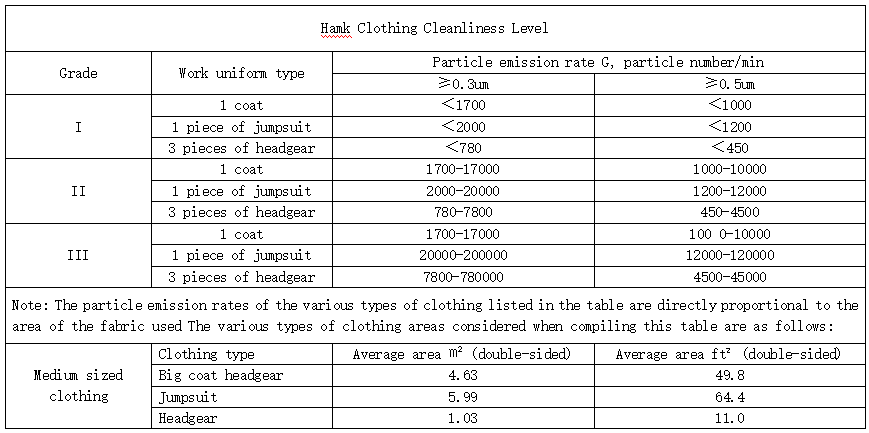

The test fabric was flipped inside a rotating cylinder, and particles on the fabric fell off under controlled conditions. The discrete particle counter samples the air inside the cylinder within the first 10 minutes of the experiment. Calculate the emission rate of particulate matter using the air particle concentration obtained from sampling, and compare it with the values in the following chart to determine the cleanliness level of specific types of clothing.

The cleanliness level of clothing refers to the cleanliness database of particles ≥ 0.5 μ m reported by Hamk in the early stage. The reason for 0.5 μ m is due to the limitations of the instruments at that time. Subsequently, the development of the instrument lowered the particle detection limit of this experiment to 0.3 μ m, and the table includes the limit values for particle cleanliness ≥ 0.3 μ m.

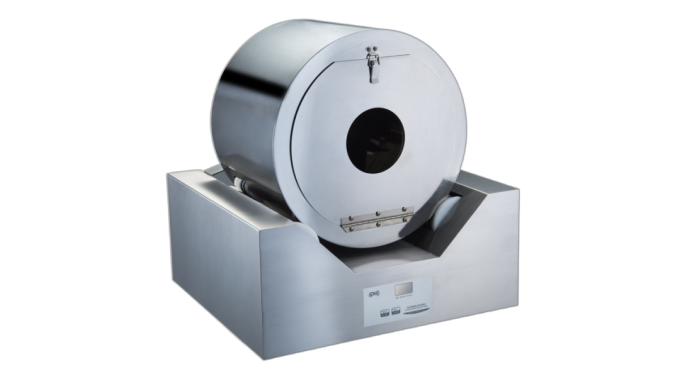

SuXin SX-Z Clean Fabric Dust Test Stand

The SX-Z clean fabric dust emission test bench is used to measure the number of particles emitted by clean fabrics during simulated motion. This simulated motion refers to the dry state of the fabric flipping in a rotating drum, measuring the number or concentration of particles emitted by the fabric within a specified time and a certain sampling amount, and comparing this measurement with the standard grade to evaluate the grade of the clean fabric.

The test bench adopts the Hamk drum mode and has obtained a national patent (patent number: 201020524113.9). At the same time, the testing standards comply with the American Society for Environmental Science and Technology standards "IESTRP-CC003.3" and "Cleanroom and Other Controlled Environment Clothing Elements", making it the preferred cleanliness testing product for clean fabric production enterprises.

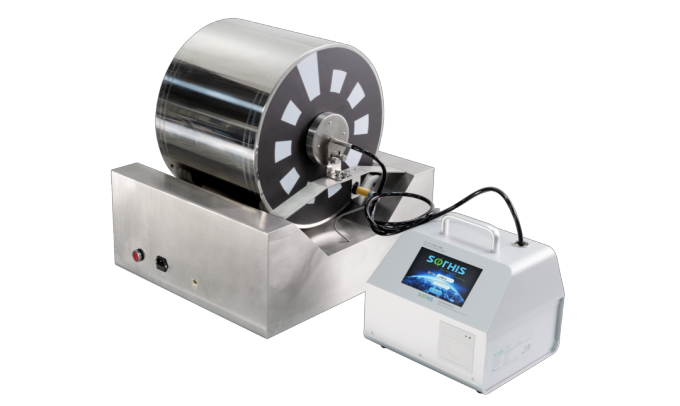

It is recommended to use the SuXin SX-L310T dust particle counter with the SX-Z clean fabric dust emission test bench. The particle counter adopts a 7-inch color touch screen, with a beautiful and atmospheric appearance. The body is made of all SUS304 stainless steel material, and the surface is sprayed with fine sand silver gray treatment; Adopting a DC brushless blower for continuous and stable operation, ultra-low noise, energy-saving and environmentally friendly; Built in imported flow sensor to achieve dynamic and precise control of sampling flow; It can be powered by AC or the built-in large capacity lithium battery to reduce power limitations during mobile detection.

The SuXin SX-L310T dust particle counter is designed according to the specifications of JJF1190-2008 and GB/T6167-2007, and is used to measure the concentration of dust particles in clean environments. It can be directly used for detection in clean environments with cleanliness levels ranging from 300000 to 100, with a sampling flow rate of 28.3L/min. The instrument is easy to operate and has a friendly human-computer interaction interface, which can conveniently, quickly, and effectively detect suspended particles in the purified environment. It is currently the preferred product for pharmaceutical and electronic factories to quickly detect the cleanliness of clean rooms.

Alright, without further ado, in addition to the Hamk drum, SuXin Environment also develops and produces particle counters, floating bacteria samplers, filter integrity testers, smoke generators, etc. If you want to learn more about cleanroom testing instruments, please leave a message in the background or call 17315823521 (WeChat same number)!