Firstly, a clean workbench can provide a sterile working environment. During the pharmaceutical process, any small impurities or contaminants can have a serious impact on the quality of the drug. The clean workbench effectively prevents microorganisms and particles from entering the air by filtering the air and maintaining positive pressure in the work area, thereby reducing the risk of drug contamination.

Secondly, a clean workbench helps protect the health of pharmaceutical workers. During the pharmaceutical process, workers may come into contact with harmful chemicals or drug components, and a clean workbench provides a closed workspace that effectively isolates workers from direct contact with harmful substances, reducing their risk of exposure to hazardous factors.

In addition, the flexibility of the clean bench is also one of the reasons why it is highly favored. They can be customized according to specific job requirements, with different sizes and functions to choose from, suitable for pharmaceutical laboratories or production sites of different sizes and types.

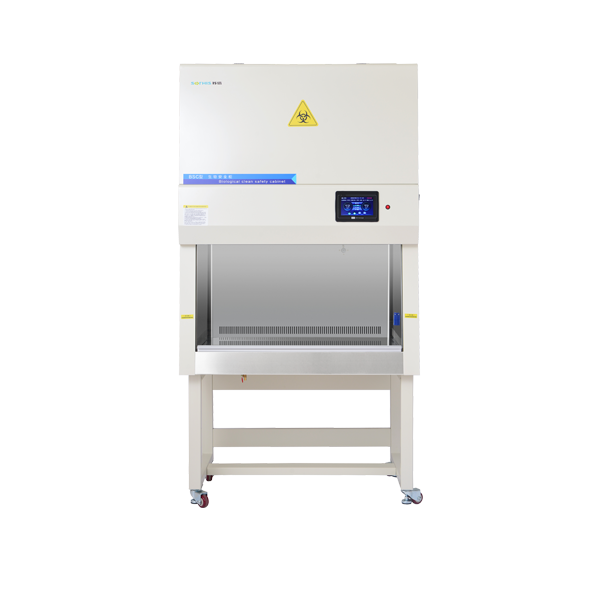

Clean workbench

Overall, clean workbenches are highly favored in the pharmaceutical industry because they provide a highly clean and sterile working environment, ensuring drug quality while protecting the health of pharmaceutical workers. These devices play an indispensable role in the pharmaceutical production process, providing important support for the development of the industry and the assurance of drug quality.

Suxin Environment is committed to producing clean workbenches, ensuring a sterile environment and employee health during the pharmaceutical process.