High efficiency filters are ideal terminal filters for industrial cleanrooms and biological cleanrooms, and are also commonly used as supporting filters for other purification equipment. The filtration efficiency of the high-efficiency filter itself is generally tested by the manufacturer, and a filter filtration efficiency test report is usually attached at the factory. For enterprises, the purpose of leak detection is to check the sealing of the high-efficiency filter and its connection with the installation frame, timely discover possible defects in the high-efficiency filter itself and during installation, take corresponding remedial measures, and ensure the cleanliness of the area.

Why do we need to conduct efficient filter leak detection?

Once the high-efficiency filter leaks, the number of dust particles and bacteria in the clean room may exceed the standard, thereby affecting product quality. The purpose of leak detection on high-efficiency filters is to identify defects in the filters and their installation, in order to take remedial measures.

Leak testing is the foundation of particle testing, and its importance is no less than particle testing.

The leak test and air flow rate have met the specified requirements, and the uniformity of the airflow is also within the specified control range, ensuring natural cleanliness.

There are two main reasons for the leakage of high-efficiency filters: first, damage to the high-efficiency filter during installation, and second, inadequate sealing during installation.

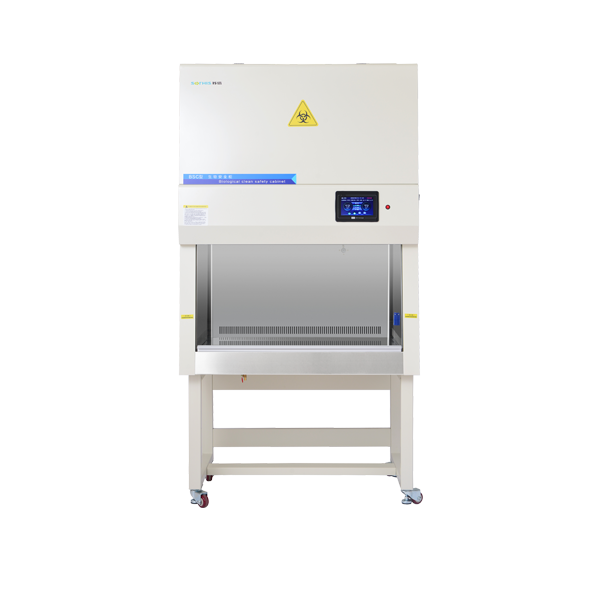

The SX-L310S high-efficiency filter counting leak detector

The SuXin SX-L310S high-efficiency filter counting leak detector is designed according to the requirements of ISO14633-3 B.6.3 and IEST-RP-CC034.2 specifications. It is a specialized instrument for scanning and leak detection of high-efficiency air vents in clean rooms (areas), consisting of an aerosol generator, a particle diluter, and a counting leak detector (equipped with a handheld intelligent scanning probe).

The SX-L310S high-efficiency filter counting leak detector uses counting method to scan and detect leaks. By combining the counting leak detector and particle counter to detect the upstream concentration of the filter, the downstream leakage point value is calculated based on the labeled efficiency of the filter. The actual scanning detection of the downstream leakage point value of the high-efficiency air outlet is compared with the calculated leakage point value to achieve leak detection of the high-efficiency air outlet. According to Appendix B.6.3 of Part III of GB/T25915 "Cleanrooms and Related Controlled Environments", the procedures for scanning leak detection using counting method are detailed. GB50591 "Code for Construction and Acceptance of Cleanrooms" recommends that counting scanning method should be preferred for leak detection.

SX-L310S Performance Advantages

• Comply with domestic and international regulatory standards;• Counting function: dynamic GMP, static GMP, ISO14644-1 level determination, UCL automatic calculation;

• Automatically determine leak point values, leak alarms, leak particle size tracking, and on-site printing;

• The upstream dust concentration is much lower than that of the photometer method, which causes less damage to the filter;

• High detection sensitivity, also applicable for leak detection of ultra efficient filters;

• Built in large capacity lithium battery, capable of continuous operation for more than 4 hours;

• It is recommended to use DEHS aerosol for low detection cost.

Selection of testing aerosols

• Aerosols used for efficient and ultra efficient filter counting scanning leak detection can include DOP, DEHS, PAO, etc., but are not limited to these substances.• The aerosol generator equipped with SuXin SX-L310S is recommended to use DEHS, which makes the upstream dust concentration much lower than the photometer method and causes less damage to the filter; The aerosols that occur can be monodisperse phase aerosols or polydisperse phase aerosols.

• However, regardless of the type of aerosol that occurs, it should be ensured that the concentration and particle size distribution of the generated aerosol remain stable during the testing process.

• When using monodisperse aerosol for counting scanning leak detection test, the deviation between the counting diameter of the tested aerosol and the MPPS of the filter material should not exceed 10%. When using multi dispersed phase aerosols for leak testing, the deviation between the counting diameter of the tested aerosol and the MPPS of the filter material can reach 50%.

Adjustment of experimental air

Before mixing with the test aerosol, the test air should be pre treated and equipped with appropriate pre filters (such as coarse, medium, and high-efficiency filters that meet national standards) to ensure its cleanliness (at least ISO7 level).

Air regulation

The test air duct should have air volume adjustment measures (such as changing the fan speed or using an air volume control valve). During the testing process, the test air volume should be able to maintain within ± 3% of the rated air volume of the tested filter.

Airflow testing

The measurement of air volume should be carried out using standard or calibrated methods (such as pressure drop testing of air volume using orifice plates, nozzles, and Venturi tubes). The maximum measurement error should not exceed 5% of the measured value.

Scanning system

• SuXin SX-L310S can choose to manually scan the filter for leak detection testing.

• The equipped counting leak detector has a handheld intelligent scanning probe, with a sampling flow rate of 28.3L/min and a recommended scanning speed of 3-5cm/s.

• The downstream aerosol delivery pipe should promptly and without loss deliver particles into the measurement chamber of the particle counter. Therefore, the conveying pipe should be as short as possible and there should be no dead bends along the way. The surface of the pipeline material is smooth and does not emit particles.