It is widely used in related industries and departments such as the pharmaceutical industry, food industry, beverages and tap water, drug testing institutes, health and epidemic prevention, hospitals, and public places.

The common sampling flow rates now include 28.3L/min, 50L/min, 100L/min, 136L/min, etc. The sampling head and sampling pump are the core components of the planktonic bacteria sampler. The integration method of the sampling head and sampling pump is different for different types of planktonic bacteria samplers. Some use split sampling heads, while others integrate the sampling head and sampling pump into one machine. To improve sampling efficiency and representativeness, high flow samplers are generally used to collect the most air samples in the shortest possible time.

At present, the sampling flow rate of planktonic bacteria is mostly 100L/min. Regardless of how the sampling head and sampling pump are integrated, we still cannot simply classify planktonic bacteria samplers based on sampling flow rate, but should distinguish them based on instrument structure and load capacity. The main indicators of the sampling head are the size and quantity of the slits or micropores.

There are two methods for calibrating the planktonic bacteria sampler, namely adjusting the target sampling time and target sampling flow rate; So as to meet the requirement of the total sampling volume of the target.

Method 1: Input the measured flow value into the sampler, i.e. correct the actual flow value. By adjusting the sampling time, even if the measured flow rate is much different from the preset flow rate, the accuracy of the total sampling volume is still guaranteed.

Method 2: Adjust the fan power to achieve the target: sampling flow rate, i.e. target flow rate value adjustment. This method is divided into hardware adjustment and software adjustment according to the adjustment steps.

For ordinary atmospheric samplers, method 1 is suitable because it emphasizes the accuracy of cumulative sampling volume. But for the planktonic bacteria sampler, not only the sampling volume is important, but also the sampling flow rate is important, because it uses the Anderson collision principle to collect planktonic bacteria from the air and culture them on agar for counting.

Due to the fact that this collection is related to the size and impact velocity of the particles, rather than the sampling time. Therefore, if there is a large deviation (usually small) in the sampling flow rate, even if the final sampling volume obtained by method 1 is accurate, only large particles are captured due to insufficient impact velocity, while small particles are missed, resulting in inaccurate measurement results and potentially causing significant losses.

Generally speaking, samplers with strong load capacity can be directly connected and detected with traditional gas sampler flow verification devices. The low load planktonic bacteria sampler can only be detected using calibration devices based on the principles of impeller anemometer or Roots flowmeter, each with its own advantages and disadvantages.

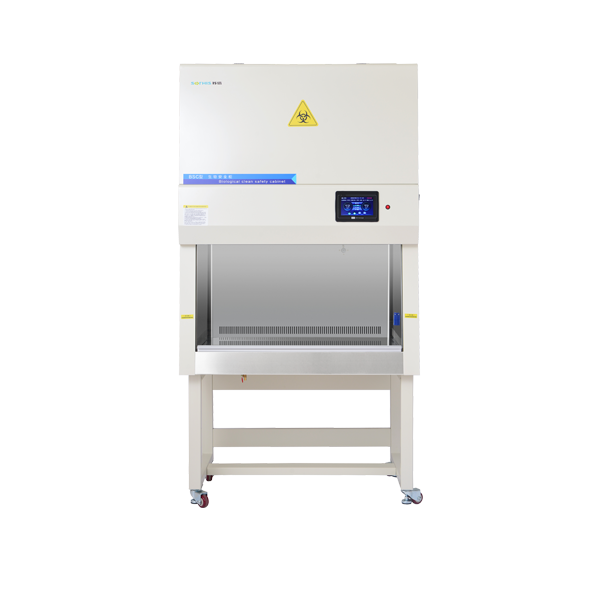

Suxin Environmental Floating Bacteria Sampler

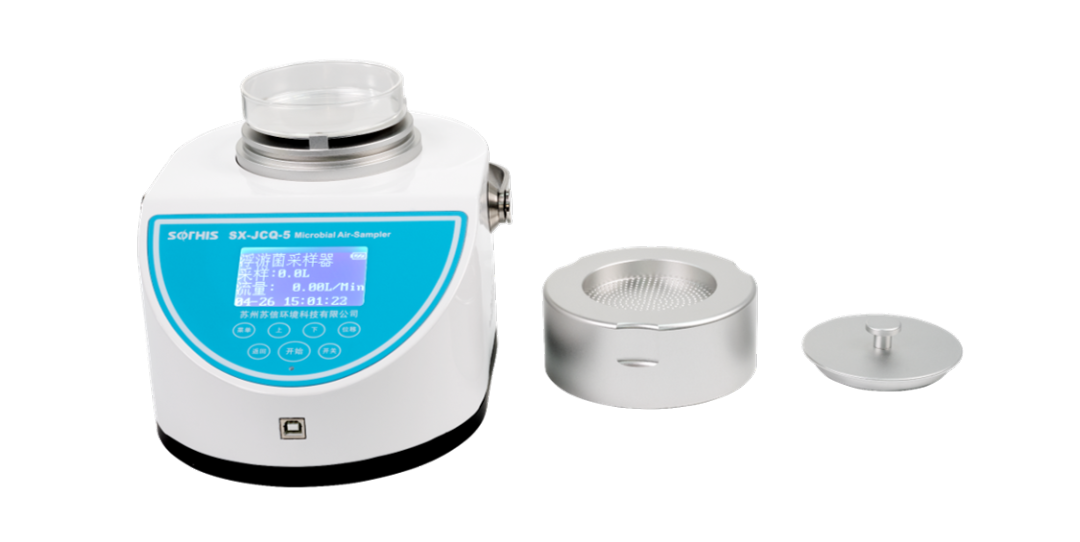

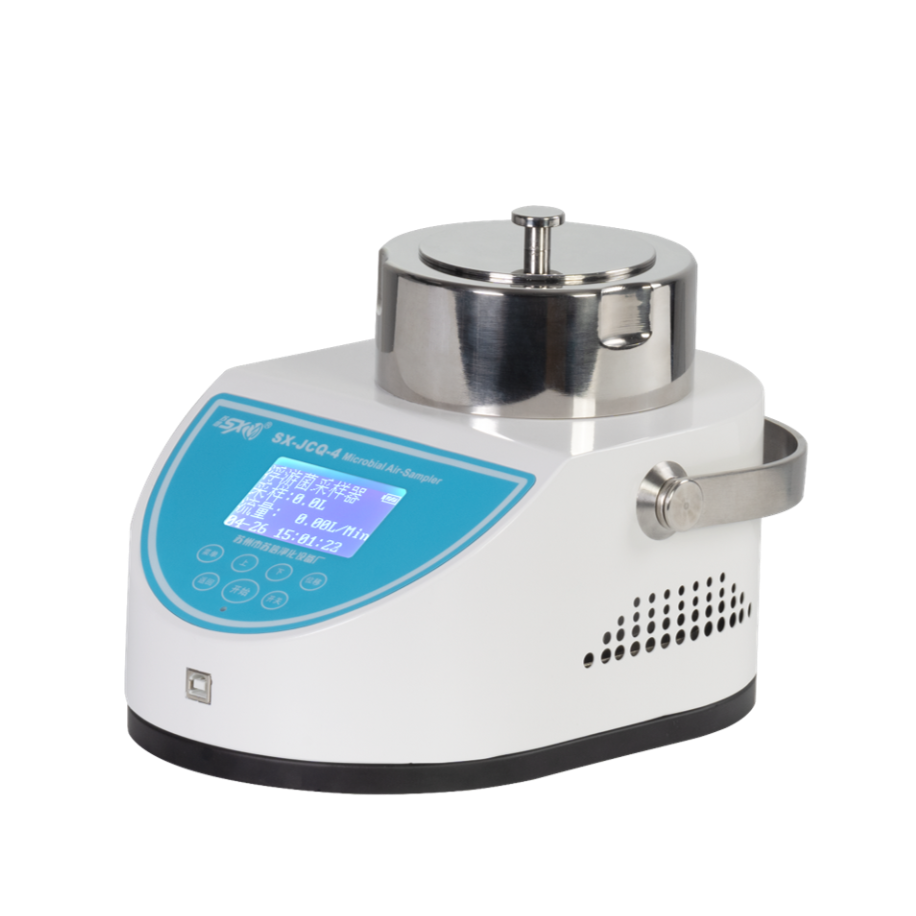

The SuXin Environment JCQ series planktonic bacteria sampler is equipped with an efficient suction device inside, which can continuously monitor the suction. The system measures air and regulates the inflow suction volume to maintain 100L/Min ± 5%. Ensure that the microbial impact rate is maintained at around 10.8m/s to achieve the highest capture rate. When external factors prevent or disrupt stable flow, the instrument's automatic wind speed adjustment device will ensure a flow rate of around 100L/Min.

Due to the pollution caused by microorganisms and dust, which can affect production and process flow, the demand for detecting environmental microorganisms (dust) has been increasing. Microbial monitoring is particularly important for industries such as pharmaceuticals, food, medical, daily chemical, and environmental protection.

Product Features

There are currently many detection methods, the vast majority of which are based on the principle of impact. With the development of SX-JCQ-4/5, the original shortcomings of the system have been eliminated, and the best aspects have been retained, ultimately designing a convenient, reliable, and accurate sampler for culture dishes.

The maximum sampling flow rate of SX-JCQ-4/5 is 100L/Min, and each sampling cycle can sample up to 6000L, suitable for sterile and clean areas that require strict monitoring.

The SX-JCQ-4/5 professional planktonic bacteria sampling head uses SUS316 material (JCQ-5 sampling head is made of aluminum alloy material) to ensure compliance with ISO14698-1 technical specifications, with a smooth and clean surface. Professional laser drilling is used to drill 0.7mm * 397 holes, ensuring a particle velocity of 10.8m/s, which captures particles larger than 1 μ m. There is no difference between the porous impact sampling method and other microbial sampling methods.

At present, sterilization workshops, laboratories, and operating rooms in industries such as pharmaceuticals, biological products, health products, beverages, and hospitals widely use the colony method to determine the number of bacteria in the air. Although this method is simple, it has many disadvantages:

1. Cannot know the number of bacteria contained in a unit volume of air;

2. Due to the slow natural sedimentation of bacteria, it is difficult to collect, with low efficiency and long collection time;

3. The sedimentation of bacteria is affected by airflow, resulting in significant errors.

The SX-JCQ-4/5 series planktonic bacteria sampler effectively avoids these problems and has the following characteristics:

Time reduction - using a high flow rate pump, bacteria collection can be completed in a very short time according to specifications;

Accurate data - the number of planktonic bacteria per unit volume can be determined by counting the number of cultivation points;

Automatic operation - The entire instrument is controlled by a single-chip microcomputer for easy operation and automatic data collection process;

Accurate results - Due to the use of the impact principle, the collection efficiency is high and not affected by environmental airflow, making the collection results more accurate.

In addition to the planktonic bacteria sampler, Suxin Environment also develops and produces dust particle counters, aerosol generators, filter integrity testers, and more. It can basically meet the needs of various industries for such products. If you want to learn more about clean room testing instruments, please leave a message in the background or call 17315823521 (WeChat same number)!