In order to implement the opinions of the State Food and Drug Administration on the reform and improvement of the radioactive drug review and approval management system, encourage drug inspection institutions with the ability and conditions to carry out the construction of technetium labeling and positronium radioactive drug inspection capacity, and increase qualified inspection institutions, the State Food and Drug Administration organized the development of technetium labeling and positronium radioactive drug inspection agency evaluation procedures, which were issued on March 7, 2024 and implemented from the date of issuance. In terms of experimental instruments and equipment, the requirements of the State Food and Drug Administration for technetium labeling and positron radiopharmaceuticals inspection agency evaluation procedure for drug inspection agencies are as follows:

(1) It should be equipped with instruments and equipment suitable for the inspection of radioactive drugs. The instruments and equipment should be divided according to the function of the inspection items, and the layout should be reasonable to avoid mutual interference of different inspection items. Refer to table 1 for the main equipment configured in the radiopharmaceutical test laboratory.

(2) The laboratory shall formulate the operation procedures, use records, maintenance, calibration plan and other relevant documents of the inspection equipment and radiation protection monitoring equipment. Ensure the normal function of the equipment and prevent pollution or performance degradation.

(3) The instruments for radiopharmaceuticals inspection should be verified, calibrated or verified. It should be equipped with instruments to check the relevant radioactive standard sources during the period, and regularly check and adjust as necessary to maintain the credibility of the calibration status.

(4) The verification, calibration or verification items of radioactive drug inspection instruments shall meet the inspection requirements.

(5) Radioactive calibration sources should be provided by competent reference material producers (those who meet the requirements of ISO17,034 are considered competent). It should be ensured that the radioactive standard source meets the inspection requirements. For example, the gamma photon energy of the standard source of the gamma spectrometer should cover the main photon energy of the nuclide to be measured, and the size, volume, medium and container material should be the same as the sample.

Table 1: main equipment recommended for technetium labeling and positron radiopharmaceuticals testing laboratory

| No. | Instrument name |

| 1 | Activity meter |

| 2 | Radioactive thin layer chromatography scanner |

| 3 | γ spectrometer |

| 4 | γ counter |

| 5 | Liquid scintillation counter |

| 6 | Lead guard case |

| 7 | Radiation dose monitor |

| 8 | Surface pollution monitor |

| 9 | Ultraviolet visible spectrophotometer |

| 10 | Gas chromatograph |

| 11 | High performance liquid chromatography (including radioactive detector) |

| 12 | Electronic analytical balance |

| 13 | pH meter |

| 14 | Micro osmometer |

| 15 | Visible foreign matter detector |

| 16 | Camera microscope |

| 17 | Electric drying oven |

| 18 | Ultra clean table or isolator |

| 19 | Precision constant temperature water bath box (or other equipment with the same function) |

| 20 | Centrifuge |

| 21 | Low temperature refrigerator |

| 22 | Steam sterilization pot |

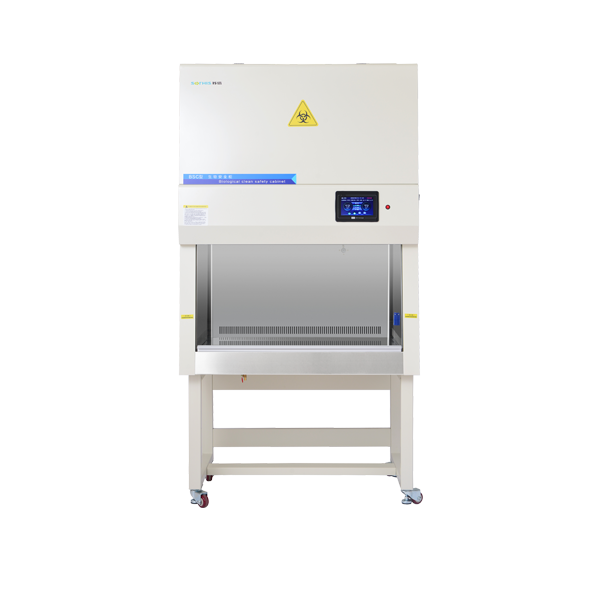

| 23 | Biosafety cabinet |

| 24 | Constant temperature incubator |

| 25 | Floating bacteria sampler |

| 26 | Dust particle counter |

| 27 | Vortex mixer |

| 28 | Ultra pure water machine |

Note: the above equipment is the basic equipment needed for technetium labeling and positron radiopharmaceuticals inspection。