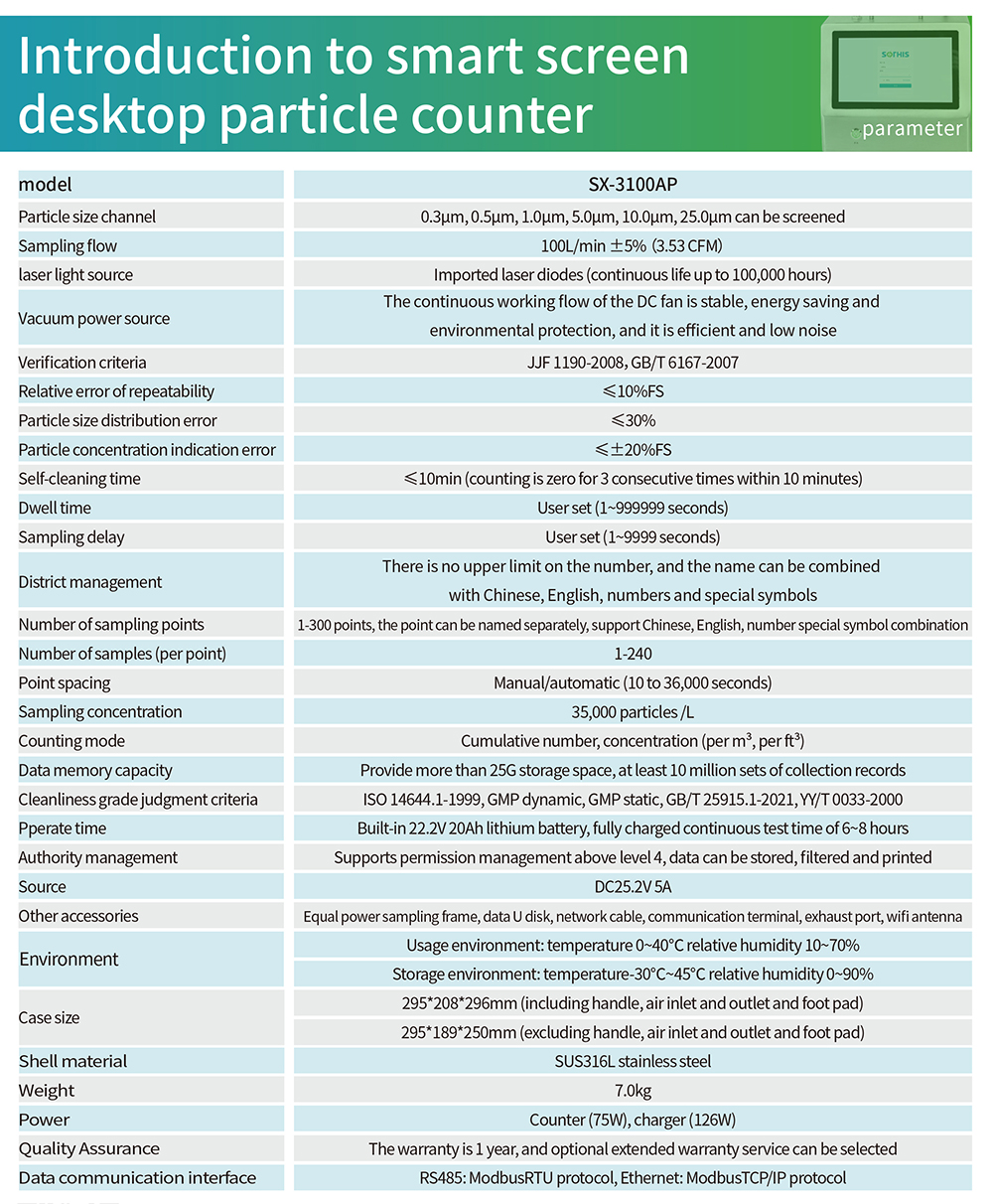

The SX-3100AP dust particle counter is a new generation intelligent screen portable dust particle counter developed by our company. The instrument adopts a color 10 inch intelligent screen, supports level 4 permission management, audit tracking, and meets FDA 21 CFR part 11. The body is made of all SUS316L stainless steel material and adopts a DC brushless blower for stable continuous operation, ultra-low noise, built-in high-efficiency filter, energy-saving and environmentally friendly; Built in imported digital flow sensor for dynamic and precise control of sampling flow; The power supply can use AC power supply and is equipped with a large capacity lithium battery pack, which is convenient for mobile detection in places without AC power. The instrument is easy to operate and has a friendly human-computer interaction interface, which can conveniently, quickly, and effectively detect suspended particles in purified environments. It is currently the preferred product for quickly detecting clean room cleanliness in industries such as biopharmaceuticals, electronic semiconductors, and new energy.

Advantages

● Provide a complete verification manual to facilitate compliance with pharmaceutical/electronic specifications

● Built-in thermal printer for data printing, setting,sampling, display and printing

● Perfect operation log and data log to record personnel operation and data storage, meeting FDA 21 CFR Part 11

● There is no limit to the number of sampling rooms and formula preset

● Rooms and points can be named separately,supporting Chinese, English, numbers and special symbols

● GMP, ISO 14644-1 and other cleanliness standards are judged

● Color 10-inch smart screen, simplified operation

● Sampling records can be used to filter the data to be queried by area/room and time

● Data analysis can be done by making trend chart analysis according to location and particle size

● Supports USB data export in xlsx, csv, pdf formats

● The particle number alarm is realized by setting the alarm parameters

● Set up separate passwords and operation permissions according to the identity of operator, auditor and administrator

● A wide range of expansion interfaces can be selected to increase temperature and humidity, pressure difference, wind speed, etc

● Support RS485: ModbusRTU protocol, Ethernet: Modbus TCP/IP protocol

Function

● Sampling flow rate: 100L/min ±5% (3.53 CFM)

● Grain size distribution error ±30%FS

● The error of the indicated concentration is ±20%FS

● Self-cleaning time, less than 10min

● The relative error of repeatability is less than or equal to 10%FS

● Complies with GMP static, GMP dynamic and ISO14644-1 standards

● Sampling concentration: 35,000 particles/l

● More than 25G of storage space, at least 1,000,000 sets of collection records

Apply

● Cleanliness testing of cleanroom (area)

● Daily maintenance and monitoring of cleanrooms in electronics and pharmaceutical factories

● Measurement of airborne particles