SuXin's "One Product per Week" Product Promotion Simulation Training

In order to enhance the structured expression ability of sales and service personnel, strengthen on-site adaptability, and respond to diverse customer inquiries. We will optimize everyone's product knowledge mastery and communication strategies through practical feedback. The specific plan is as follows:

Weekly Product Promotion Simulation

Time: 2-3 times a week, specific time subject to company group training notice

All sales staff, e-commerce, customer service and other personnel

Simulated product

The specific products involved will start with the following instrument series, and then proceed to online, equipment, etc

|

Product |

Model |

|

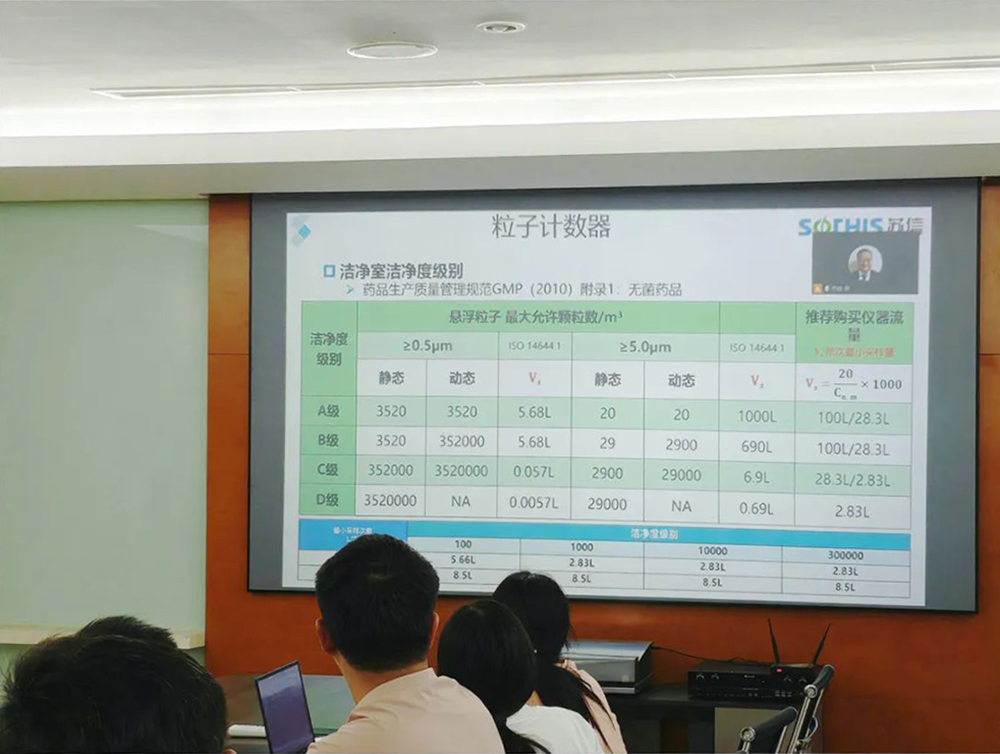

Particle counter |

Randomly select 301A, 310A, 301H, 3100AL, 3100AP, 110A |

|

Planktonic bacteria sampler |

JCQ-6 |

|

Airflow meter |

FL-1,FL-2 |

|

Wind vent leak detector |

Particle leak detection kit or photometer kit |

|

Smoke generator |

SX-SG-6500 |

|

Pressure relief valve |

PR-10.PR-100 |

The "one product per week" product promotion simulation training is mainly used to enhance the sales team's clarity of product introduction, ability to respond to customer inquiries, and mastery of product knowledge. By simulating sales scenarios, test the salesperson's understanding and adaptability of the product. Salespeople need to prepare materials, but cannot rely solely on PPT. They need to explain based on actual situations. The scoring system requires each person to answer three random questions, with a total score of 100 points. The product introduction should include features, parameters, market advantages, etc.