01 Project Background

A leading lithium battery manufacturer has deployed an online cleanliness monitoring system in the battery production process (coating, slitting, winding/laminating, liquid injection, etc.) to meet the high energy density and safety requirements of power batteries. This system solves the problems of low efficiency and data lag in traditional manual sampling and testing, ensuring that the production environment complies with ISO 14644-1 Class 5 (Class 100) and Class 6 (Class 1000) cleanliness standards.

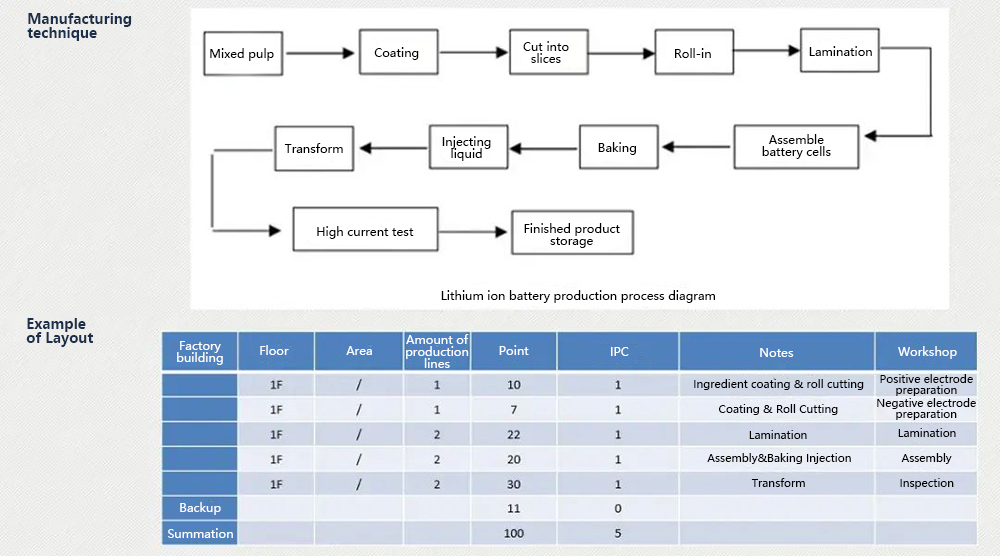

Production process flow and layout diagram

02 Core Challenge

Risk of loss of cleanliness due to dust and metal particle adhesion causing micro short circuits in batteries, resulting in a yield rate of less than 97%; Temperature and humidity fluctuations (standard requirement: temperature 22 ± 2 ℃, humidity ≤ 1%) affect the infiltration effect of electrolyte; High labor costs, traditional handheld particle counters take a long time for single point sampling and cannot cover key areas such as above the winding machine and at the outlet of the coating oven; Difficulty in tracing sudden pollution incidents and inability to locate them in real time, as well as the lack of historical data, have led to delays in root cause analysis. Excessive pollutants such as graphene can cause blockages in particle counters, contaminate flow sensors, and result in the failure of flow sensors and overall particle counters. Interference with large electromechanical equipment can cause serious electromagnetic interference and affect monitoring data.

03 Solution: Intelligent online monitoring system

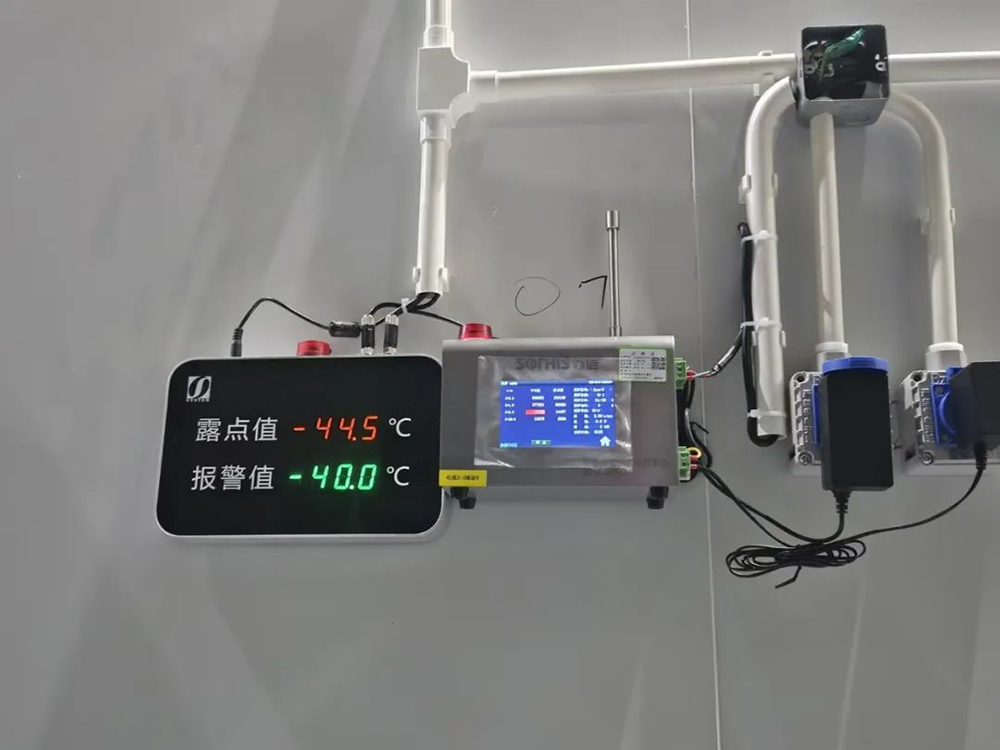

1. System architecture perception layer: Deploy laser particle counters (0.3 μ m/0.5 μ m/1 μ m/5 μ m), temperature and humidity sensors, pressure difference sensors, dew point sensors; Transport layer: Shielded twisted pair cables are used to strictly follow the hand in hand topology, avoiding star/fork connections to sensors, and data transmission is achieved through Modbus/RS485 protocol; Platform layer: EMS online monitoring platform integrates SPC statistical analysis, 3D workshop modeling, and over limit warning (email/audio-visual alarm);

Interaction layer: central control large screen display+multi-level permission management.

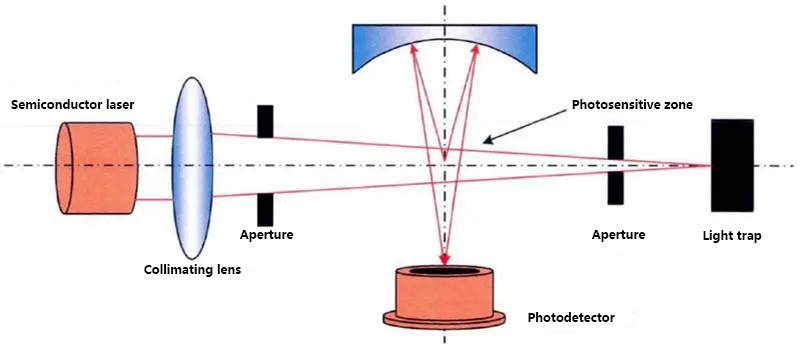

2. Excellent optical system with key technology: We use self-developed customized composite lenses to manufacture highly average strip-shaped light spots, ensuring that the energy of particles entering the photosensitive area is consistent and counting is more accurate;

Principle diagram

Average stripe spot

A stable and pollution resistant flow detection method: utilizing the characteristics of the flow channel to design a dedicated structure to achieve accurate flow measurement, solving the problem of easy pollution and inaccurate measurement of thermal flow sensors after a period of operation, and improving the stability and consistency of flow measurement;

Multiple anti-interference technologies: optimize the ultra-low noise power supply system to control power supply noise within ± 5mV; By designing specialized shielding components, external interference

shielding of sensor core components can be achieved; Referring to electromagnetic compatibility design specifications, effectively introducing static electricity and electromagnetic compatibility noise from the shell into the ground;

Add interface filters to effectively suppress electromagnetic interference and noise and optimize signal transmission quality;

Digital Twin: Linking environmental data with production batch numbers to achieve precise correlation between defective cells and pollution events

04 Implementation effect

Significantly reducing labor costs without requiring team members to fix daily measurement data; Real time monitoring and automatic uploading of data, eliminating the need for manual data entry and eliminating doubts about data fraud; Provide real-time monitoring data of the entire lifecycle environment based on different batches of products; 24-hour continuous monitoring avoids the problem of manual sampling data lag and facilitates timely handling of anomalies;

05 Industry Innovation Points

Multi parameter fusion monitoring incorporates particle concentration, temperature and humidity, wind speed, and dew point into the same evaluation model to construct a lithium battery specific cleanliness index (LCI). The closed-loop control system automatically adjusts the air volume of the fresh air unit, triggers FFU speed regulation, and initiates emergency purification within 30 seconds in areas exceeding the standard. Compliance management automatically generates audit trail reports that comply with FDA 21 CFR Part 11 standards, meeting the requirements of overseas customer factory inspections.

06 Conclusion

This case validates the core value of online cleanliness monitoring system in lithium battery mass production: through real-time data-driven decision-making, enterprises have achieved a transformation from "passive error correction" to "active defense", providing reliable guarantees for improving the consistency of automotive grade batteries. In the future, it can be further expanded to dust-free assembly of solid-state batteries, dust explosion prevention in recycling and dismantling workshops, and other scenarios.

Stacking workshop

Assembly shop

Testing workshop