The 0.1 μ m dust particle counter adopts advanced laser scattering principle and can accurately measure dust particles of 0.1 μ m and above in the air. Its high precision and sensitivity make it widely applicable in fields such as semiconductor manufacturing, pharmaceutical production, and clean room testing. Users only need to place the instrument in the testing environment to quickly obtain accurate dust particle concentration data. At the same time, the instrument also has functions such as data storage and export, making it convenient for users to analyze and process data.

Research and Development Background

Due to the continuous development of global artificial intelligence (AI) and high-performance computing (HPC), it is expected that the semiconductor industry will achieve a growth rate of 15% by 2025. These demands will drive the semiconductor industry's advanced manufacturing processes, such as processes and packaging technologies, into a phase of rapid development. In the semiconductor manufacturing process, high cleanliness is required. In processes such as photolithography, etching, and thin film deposition, improving cleanliness can increase the completion of the process, thereby reducing chip defect rates and generating high economic benefits.

Particle count is one of the important indicators for measuring cleanliness, usually expressed as the number of particles of specific sizes (such as 0.1 μ m, 0.3 μ m, 0.5 μ m, etc.) per cubic meter of air. As the chip manufacturing process shrinks, the control of particle size becomes increasingly important, especially for particles of 0.1 μ m and below, which will have a significant impact on the yield of chips. For example, in chip manufacturing processes of 28nm and below, particles of 0.1 μ m may cause chip failure. Controlling the number of particles not only affects chip performance and reliability, but also affects chip yield. Therefore, controlling the number of small particles is crucial for improving chip production efficiency.

Specially developed

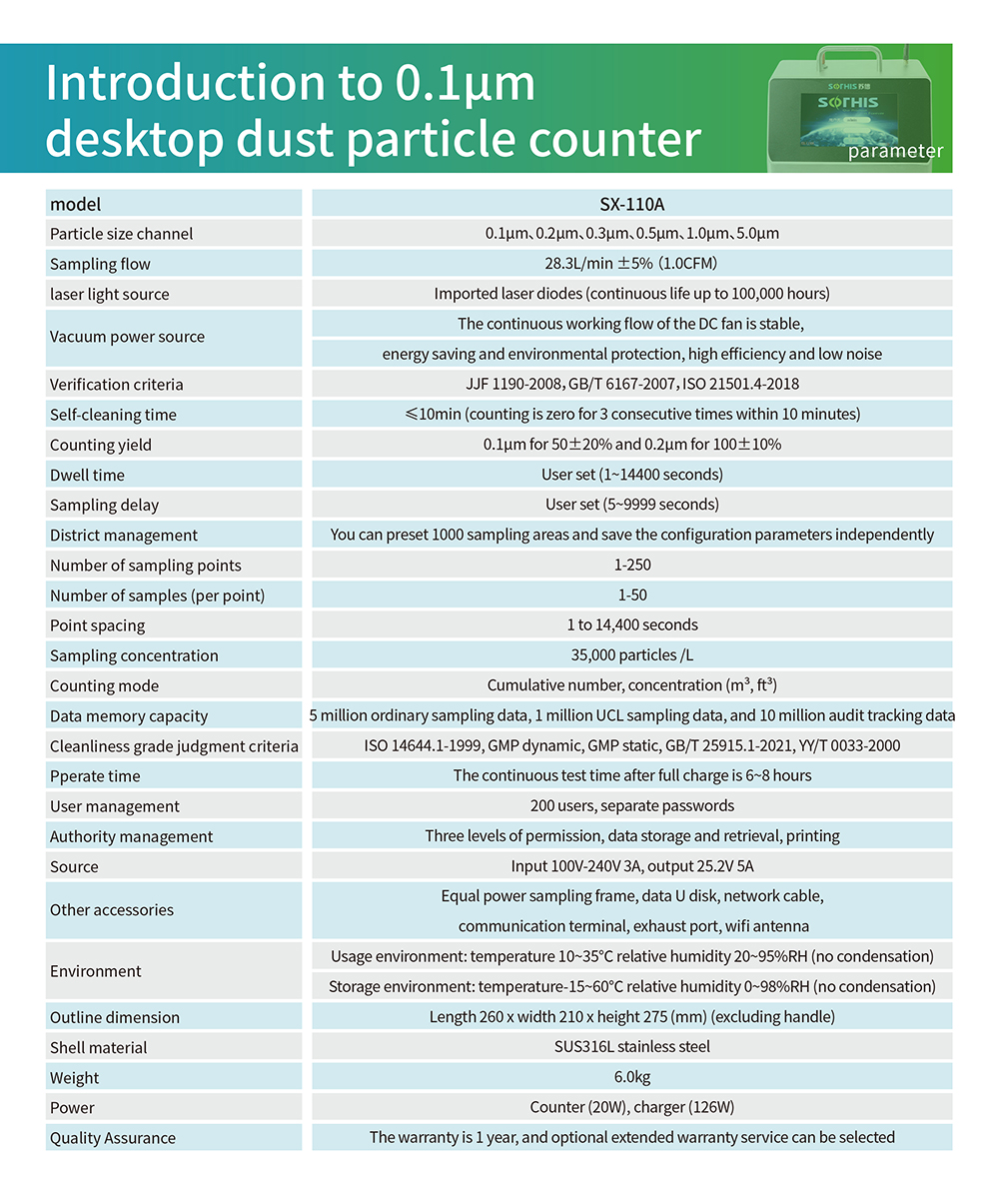

Based on the needs of the semiconductor industry, Suxin Environment has developed the 0.1 μ m dust particle counter SX-110T. By using advanced laser scattering principles and high-precision optical sensors, combined with intelligent algorithm optimization, it can detect particles with a particle size channel of 0.1 μ m, achieving efficient identification and accurate counting of small particles. At the same time, the 0.1 μ m dust particle counter also has advanced functions such as digital calibration and accurate monitoring, providing users with a more convenient and intelligent monitoring experience, becoming the preferred testing option for electronic semiconductor manufacturers.

Operational Intelligence

This product supports six particle size channel detection, including 0.1 μ m, 0.2 μ m, 0.3 μ m, 0.5 μ m, 1.0 μ m, and 5.0 μ m, which can fully meet the requirements of cleanliness level determination, accurately identify the number of dust particles, and safeguard the semiconductor manufacturing process. The sampling gas volume of this dust particle counter is 28.3L/min ± 5% (1CFM), with a sampling concentration of 35000 particles/liter, which can effectively detect the number of particles in the air. In terms of intelligent operation, the instrument has also been upgraded and optimized, using a 7-inch color touch screen, and gloves can also be worn for touch screen operation. And it can also pre-set the sampling area, select the detection particle size channel, and automatically determine the ISO14644-1 cleanliness level standard after detection. These functions provide great convenience for operating instruments during testing in semiconductor factories.

Powerful function

1. DC brushless blower, stable continuous operation;

2. Built in digital flow sensor for accurate control of flow rate;

3. Built in thermal printer for sampling data printing, convenient for data retention and viewing;

4. Support audit tracking function, capable of long-term data storage, and data can be exported from a USB flash drive;

5. Can store 1-10000 sets of measurement data, which can be queried;

6. Having three-level management permissions, setting independent passwords and operating permissions based on the different identities of operators, auditors, and administrators;

Authoritative calibration

Through the JJF1190-2008 "Dust Particle Counter Calibration Specification" of Suzhou Metrology and Testing Institute, authoritative calibration has been obtained, and the quality of testing is guaranteed.

Widely used

This dust particle counter can not only be used for cleanliness detection in the semiconductor industry, but also for daily maintenance and monitoring in industries such as optics, chemistry, food, cosmetics, medicine and health, biological products, aerospace cleanrooms, etc. It can accurately measure the number of suspended particles in the air, ensuring the smooth completion of the production process.

The Su Xin 0.1 μ m dust particle counter is a perfect combination of technological strength and market demand. Every product of SuXin is a manifestation of SuXin's relentless pursuit of "precision, efficiency, and intelligence". In the future, Suxin will continue to adhere to the development concept of "innovation leads the future", constantly explore the unknown, provide better and more efficient solutions for global customers, and jointly promote industry progress and development. Let us look forward together, under the guidance of Su Xin, the purity and beauty of the microscopic world will be within reach.